Handicraft porcelain making

Get to know the technology of Herend Porcelain Manufactory comprising centuries of expertise.

Get an insight into the steps of manufacturing and decorating porcelain all the way from raw materials to the final phase of painting.

Technology gallery

THE RAW MATERIAL

Kaolin is the most important raw material of porcelain manufacturing apart from feldspar and quartz.

PLASTER MOULD MAKING

The negative of the porcelain product is being made, that is the aid of porcelain manufacturing.

PLASTIC PASTE FOR THROWING

From the raw materials, after mixing with water, we acquire two kinds of pastes: in the picture you can see the pressing of the viscous throwing paste.

LIQUID PASTE FOR CASTING

The more viscous casting paste is produced by the addition of extra water and other additives.

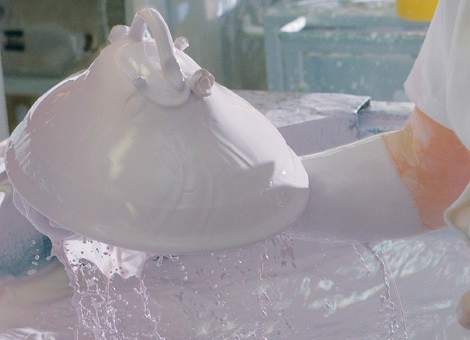

CASTING

The plaster mould absorbs a significant portion of the water content of the paste, and the solid grains stick to the wall of the mould: thus an object fitting the plaster mould can be obtained.

WOVEN PORCELAIN BASKET - FINAL TOUCH-UPS

The shape of the woven basket is achieved by strands that are rolled and fitted individually.

PORCELAIN ROSE - FIRST PETALS

Bewitching hands shape and put together the various flowers, petal by petal.

PUTTING THE FIGURE TOGETHER

This is the way pieces made of several parts - typically figures - are put together.

THE TOOL FOR OPEN-WORK

With a special double-edged knife, the open-work is effected with extreme precision.

FIRST, BISCUIT FIRING

Expert hands prepare the raw porcelain objects for the first firing, which is performed at ca. 950°C.

SECOND, GLOST FIRING

The glaze is fired at a higher (ca. 1400°C) temperature, and the object gains its glistening shine.